Visual Inspection is the most performed inspection type in Oil & Gas industry — 80% of all inspection are VT. For documentation and reporting purposes the inspector uses camera and video footage. Today’s cameras make it possible to safely and remotely inspect most hard to reach locations. The camera is typically mounted on a pole to reach the location of interest. Using RVI, the reach and precision of these inspections are greatly increased.

We provide more Specialized Systems, including long and ultra long-range and vertical crawlers. For unscheduled assessments, hazardous interventions, confined space tooling, emergency inspections and more, Arise Provides a full range of Robotic tools and technologies that can be adopted and customized for your specific needs.

Benefits

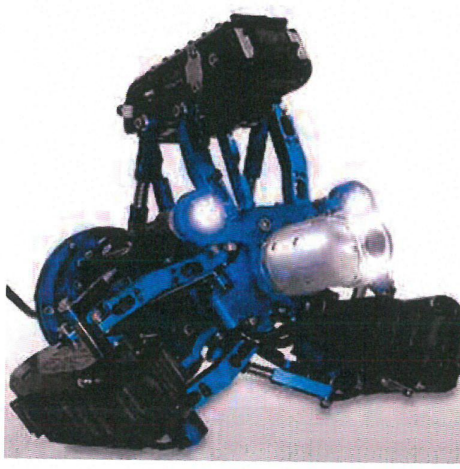

This remote visual inspection system gets into areas that are simply inaccessible with other technologies and provides a clear view of real-time conditions of capital assets and aging infrastructure. This pipe crawler robot is the industrial solution to otherwise inaccessible confined spaces including heat exchangers, coiled tubing, drill riser auxiliary lines, and small diameter water or sewer service lines. The miniature inspection robot works in air or underwater making it ideal for mining shaft and borehole inspection, confined spaces entry in nuclear facilities, onshore and offshore oil and gas pipeline inspection and for upstream to downstream pipe inspection in the petrochemical industry.

Applications