"Achieve Optimized Inspection Plan as per API 580/581 to Minimize the Lost Production and Downtime without Compromising Safety and the Environment with ISSCO”

Risk Based Inspection (RBI) is a decision making methodology to optimize inspection activities to ensure pressure systems integrity management through a systematic risk analysis. RBI is based on a Risk Assessment as per API 580/581 where this risk identifies the safe operating windows for particular process equipment, for example static equipment or pipework via consideration of the likelihood of failure and consequence of failure.

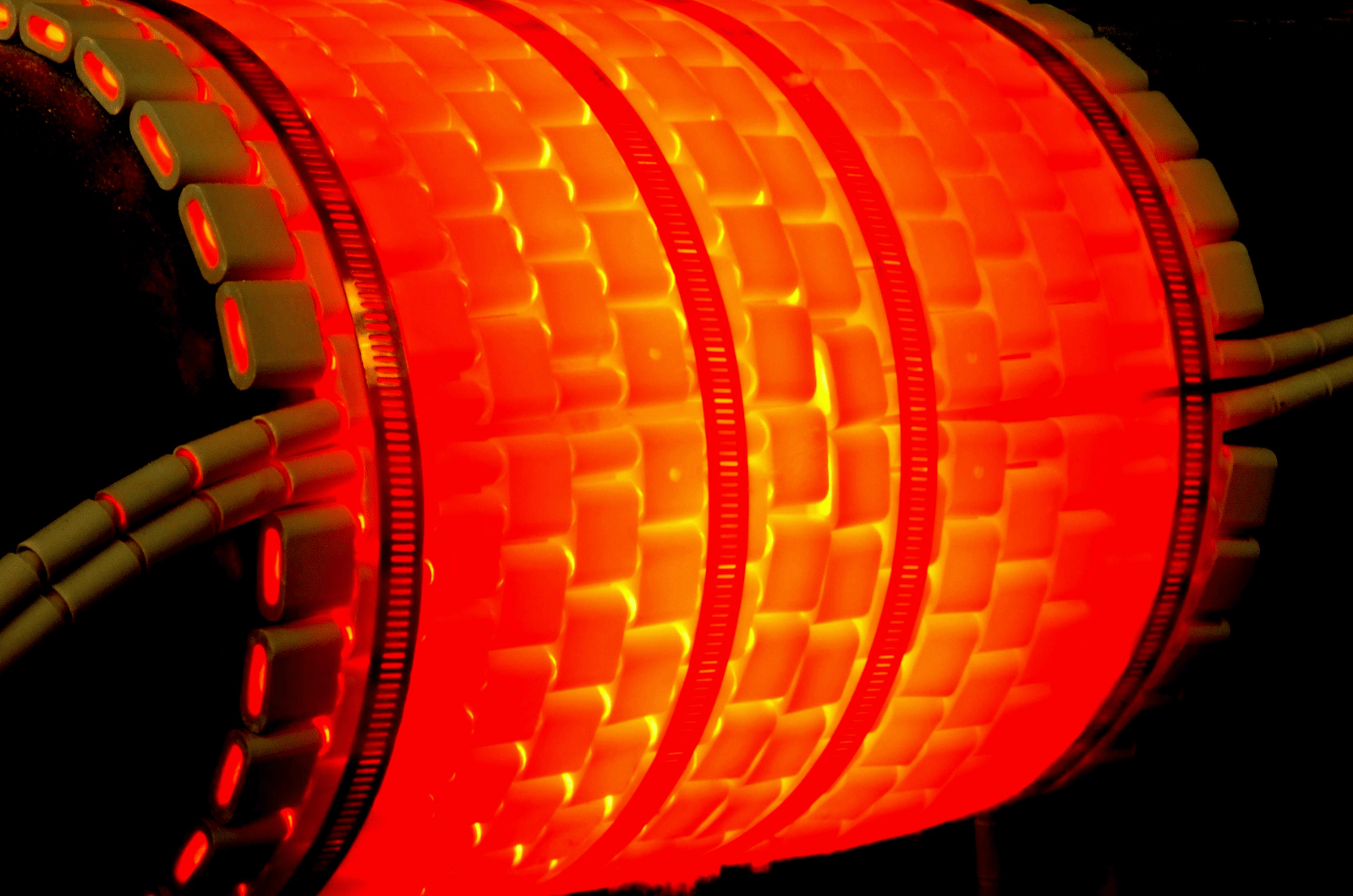

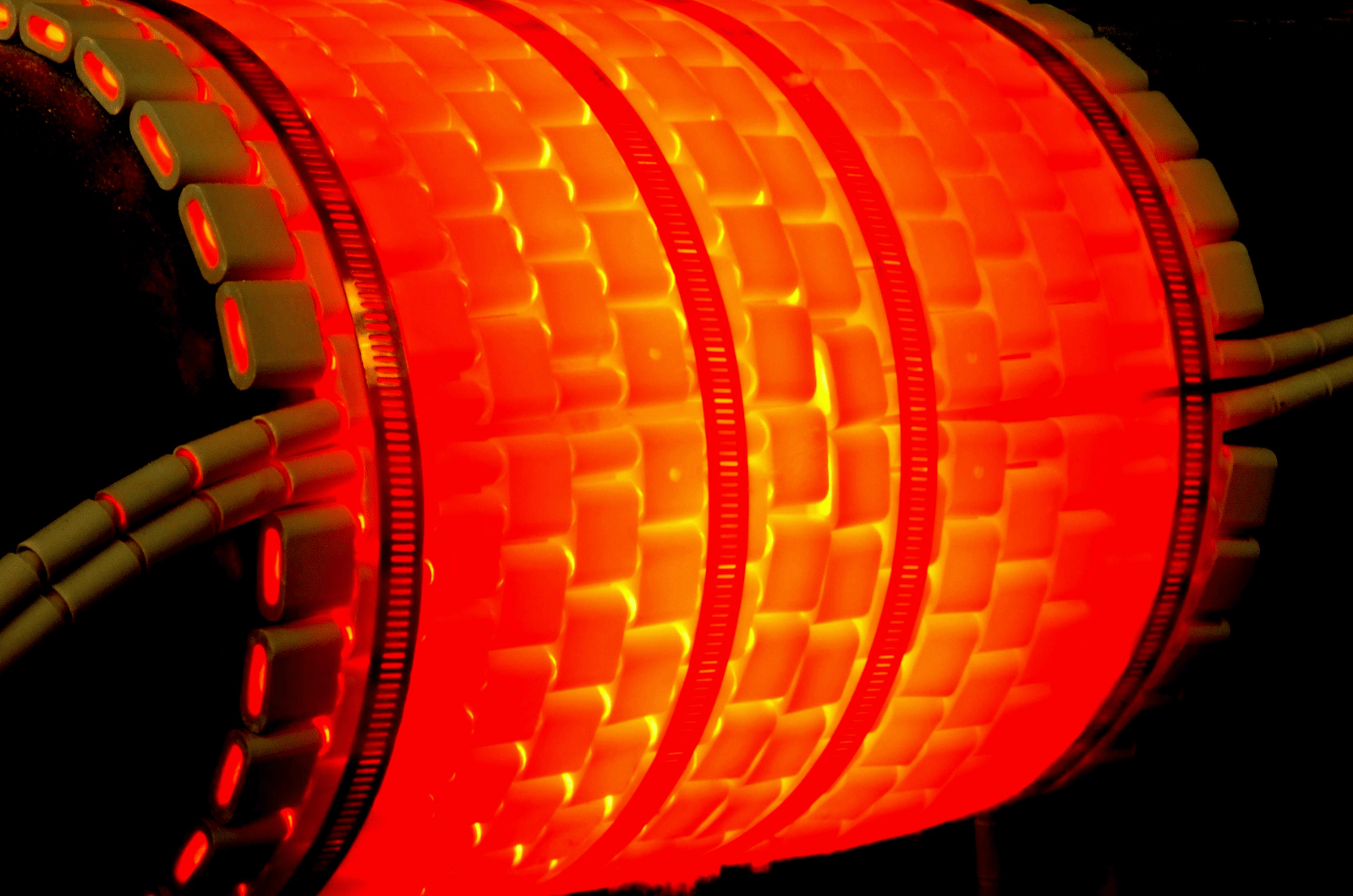

Poorly maintained resources can cause instability and partially or completely pause the production. Malfunctioning equipment or complete breakdowns can become a costly process for most companies. When breakdowns occur the labor cost per unit rises as time passes until the equipment again run as normal. Before the equipment again run as usual, there will be unexpected expenses to repair the problems, which includes extra costs for repair facilities, technician / repair crew, preventive maintenance inspections and spare parts. These are some examples of what a company can expect to deal with over time, if a reliable maintenance management solution is not installed – even for companies with new machines in their production.

IMMUSCO strategy is completely in line with API 580/581 methodologies and with company and plant objectives towards plant availability and safety. The implementation of ISSCO’s RBI can provide cost benefit and optimized inspection plans for plants fixed equipment