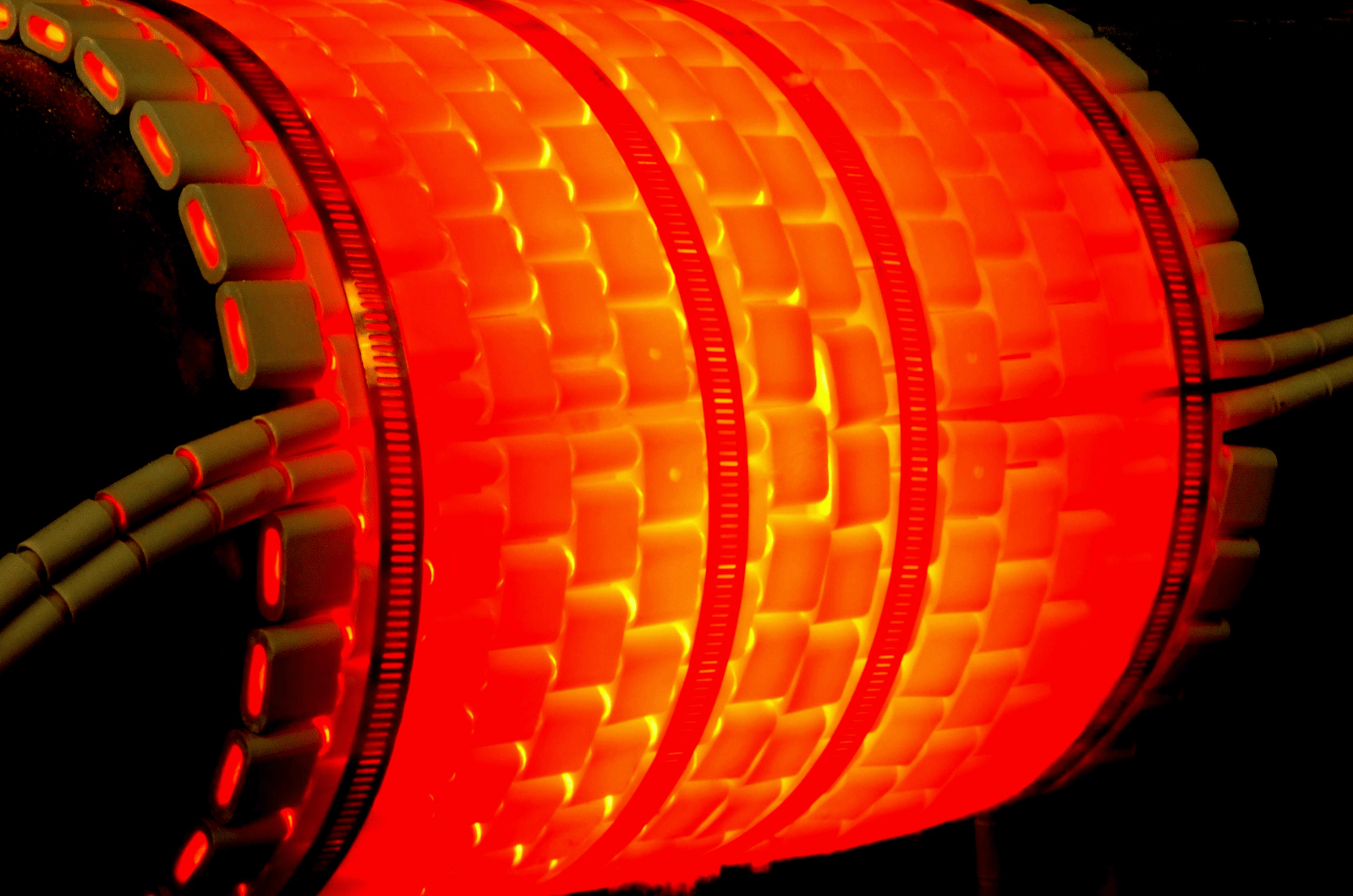

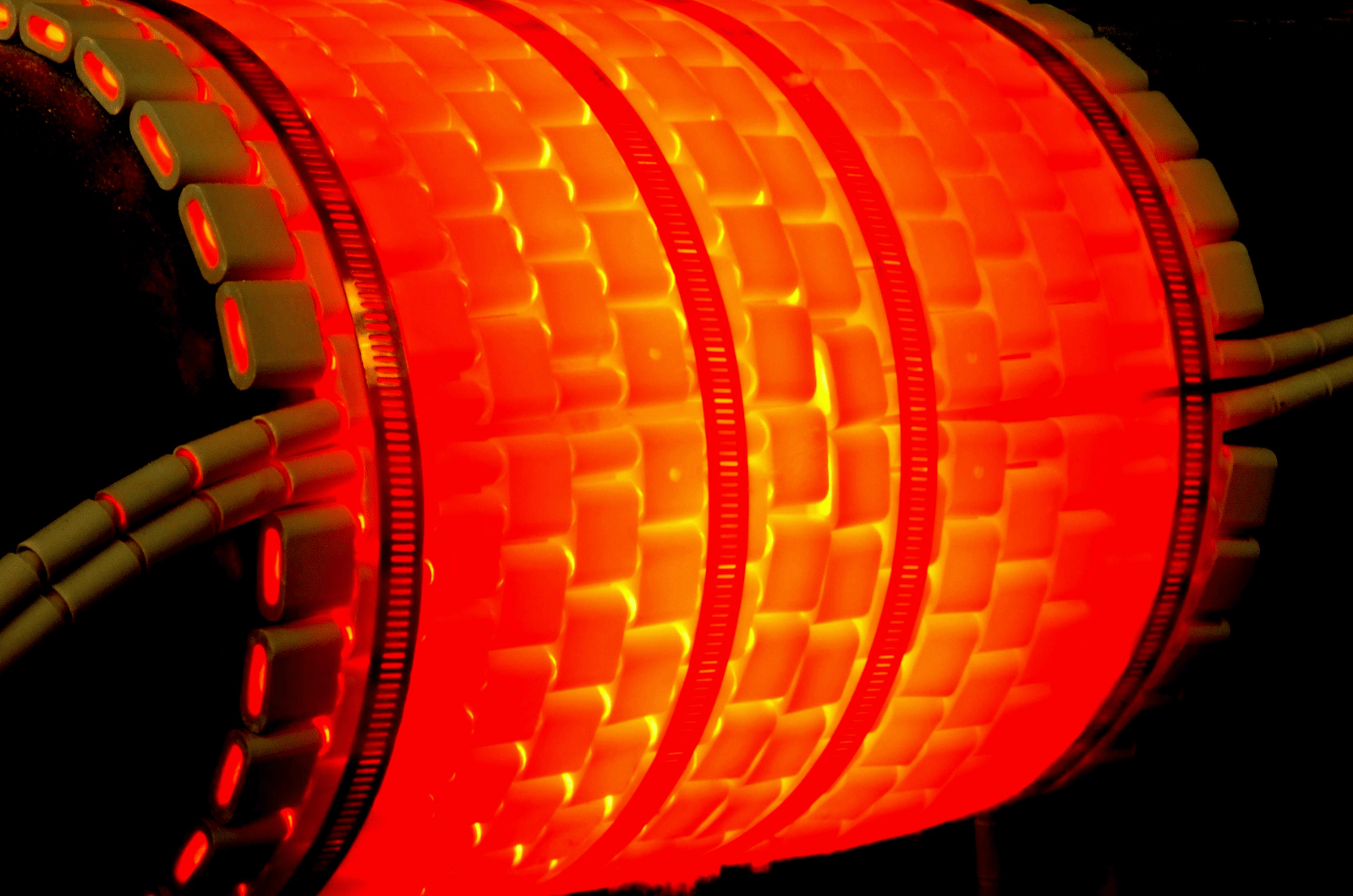

Hardness testing in non-destructive testing (NDT) measures a material's resistance to deformation, providing insights into its mechanical properties without causing damage. Common methods include the Brinell, Rockwell, and Vickers tests, which use indenters to apply controlled force and assess hardness based on indentation size or depth. Portable hardness testers are often used for on-site inspections in industries like oil and gas, manufacturing, and construction. Hardness testing helps detect material degradation, verify heat treatment processes, and ensure components meet specified hardness criteria. It is essential for quality control, ensuring the reliability and safety of critical components.

ISSCO provide two kind of hardness testing methods

This technique measures the hardness of a material by analyzing the rebound speed of an impactor, offering quick and non-destructive results.

UCI uses ultrasonic vibrations to measure hardness by evaluating the penetration of a diamond-tipped probe, providing precise hardness readings for various materials.