Positive Material Identification (PMI) is the analysis of a material, this can be any material but is generally used for the analysis of metallic alloy to establish composition by reading the quantities by percentage of its constituent elements. Typical methods for PMI include X-ray fluorescence (XRF) and Optical Emission Spectroscopy (OES).

PMI is a portable method of analysis and can be used in the field on components. X-ray fluorescence (XRF) PMI cannot detect small elements such as carbon. This means that when undertaking analysis of stainless steels such as grades 304 and 316 the low carbon 'L' variant cannot be determined. This however can be analyzed with Optical Emission Spectrometry (OES).

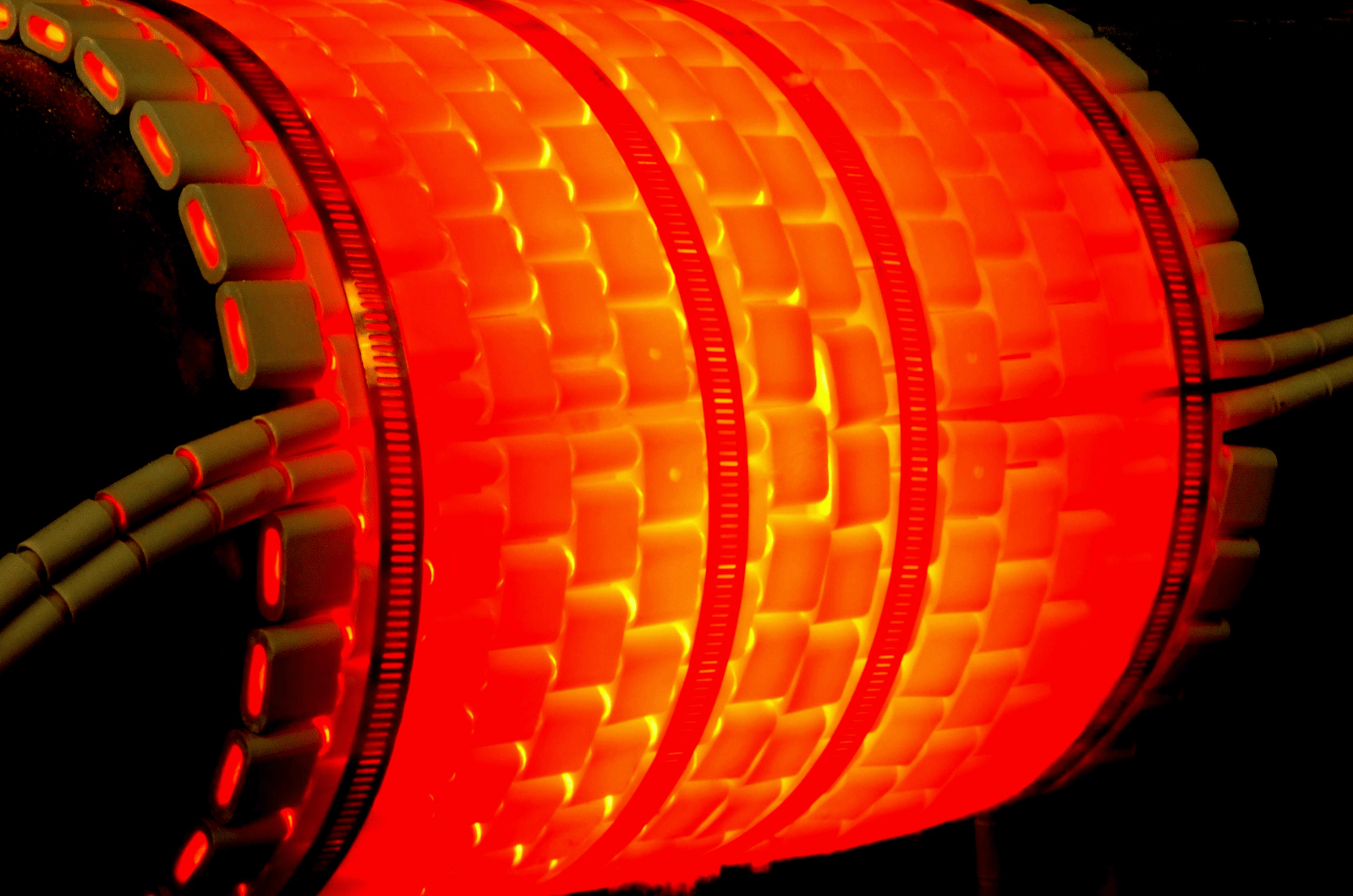

PMI testing with XRF Analyzers offers versatility across all component sizes and shapes, providing consistent and repeatable results for quick material analyses in diverse environments. It is a valuable tool in situations where material composition is unknown, documentation is missing, or samples cannot be removed for routine testing. The Smart OES portable chemical analyzer, such as the Hitachi PMI Master, utilizes Optical Emission Spectroscopy to accurately determine alloy compositions through plasma burns and elemental wavelength measurements.

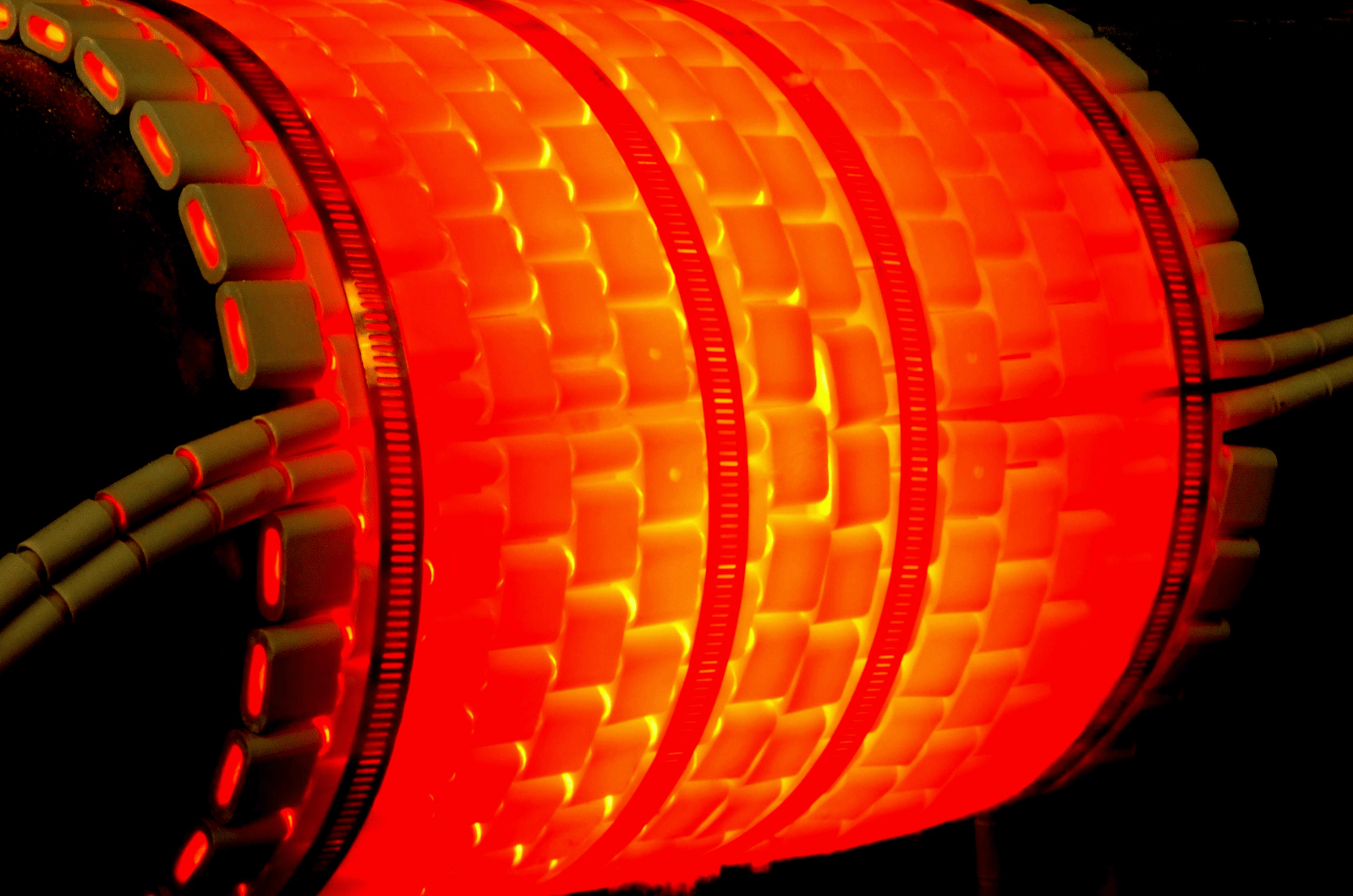

PMI is invaluable for verifying material composition when documentation is absent, ensuring accuracy without the need for sample removal. This method is particularly useful in critical equipment assessments where material integrity is paramount, and traditional testing methods are impractical. The portable nature of XRF Analyzers makes PMI testing efficient and effective across various industrial settings.